Industry insights

The latest knowledge and insights from our team of experts

Our wipes are PRI QPL certified for use in critical aerospace applications

In a highly regulated industry, there is a clear difference between a certified wipe and one that meets the minimum requirements for the application. Our CNM3A and CNM3KA wipes are qualified to the highly regarded AMS 3819D aerospace standard.

Is your cleaning routine endangering the integrity of your cleanroom?

Q+ cleanroom wipes and consumables are precisely measured and engineered to minimise particle release and reduce the contamination risk for critical clean spaces.

Q+ cleanroom consumables: pure from the start

Many of the everyday items we depend upon – simply wouldn’t be possible without cleanrooms.

Q+ cleanroom consumables are designed, engineered and controlled in Europe and manufactured to ensure minimum contamination.

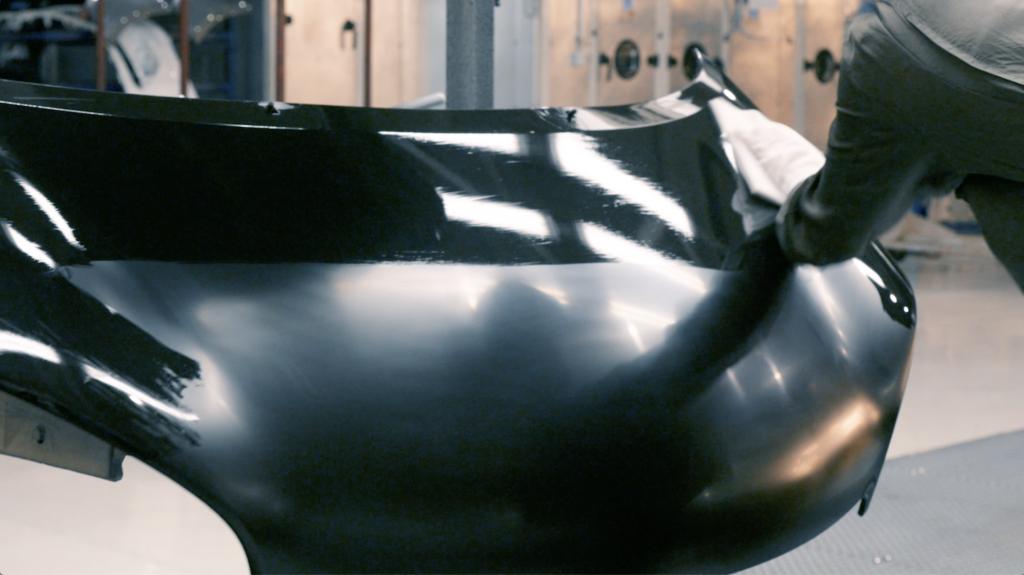

Gekatex Technical Wiping: optimise your process

From degreasing an aircraft prior to paint application, to ensuring that a mould has been efficiently primed with a releasing agent - our aim is to support you in improving your processes and delivering the best and most comprehensive results.

Gekatex Technical Wiping solutions are made from different fabrics and engineered materials to provide the best outcome in your application.

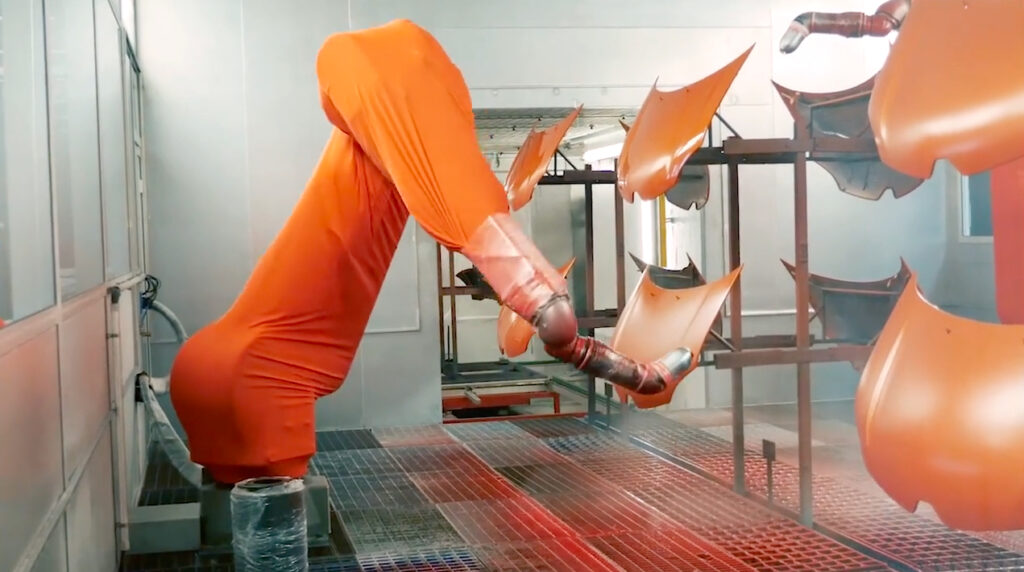

Botprotek: industrial robot covers and protection

Robots bring huge benefits to industrial processes – but, robots require a considerable initial investment. So, how can you protect your capital investment and ensure better ROI from your robot?

Botprotek is a brand of the Gekatex Group that develops and manufactures protective covers for robots and industrial equipment.

Gekatex PRI QPL qualification

In its constant improvement process, Gekatex has now qualified its CNM3A and CNM3KA technical wipes as PRI QPL.

G-Light PQE – surface inspection torch and contamination detector

The G-Light PQE can be used to check surfaces, tools and parts, to keep particles and contamination at minimum levels during painting and other critical stages of production.

Our role in the automotive OEM process

We supply multiple products for all stages in the automotive process - our team of experts will help you choose the right product for your application