Research & development

Innovation, development and certification

We invest 2.5% of our turnover back into the research and development of new and existing products. This investment in innovation reflects our commitment in delivering the most effective solutions for our customers.

We have dedicated experts for each of our key brands and our purpose-built, in-house laboratories in Europe and China enable our teams to test and verify our products and solutions – to ensure our raw materials achieve the highest standards and that our finished products are stable. They also provide the capability for us to develop new products, and explore new applications for our existing ones – including breakthrough solutions for our customers.

Our laboratories are equipped for analysis, application and material characterisation testing

We will also acquire hire additional independent laboratories and equipment as necessary for additional testing that we cannot fully support in-house. For high specification testing, we utilise reputable external laboratories.

We continuously build upon our existing knowledge and understanding of solvents, different surfaces, applications, standards, textile bases and related topics – and this is captured in our constantly growing database.

Certificate of Analysis

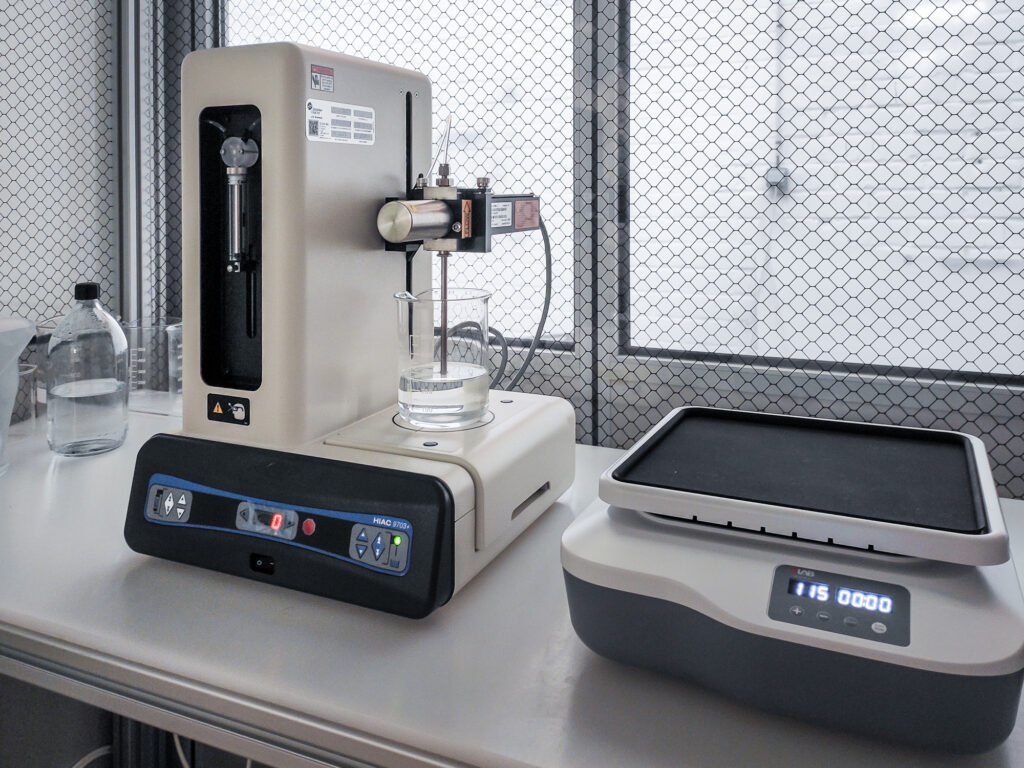

Our dedicated lab and Liquid Particle Count (LPC) equipment, enable us to assess the contamination potential of our products and complete analysis in-house.

This capability means that we can supply a Certificate of Analysis (COA) with our products.

Many manufacturers supply a Certificate of Conformity (COC) with their products to verify alignment with regulations in a top-level, average score.

Q+ cleanroom products are additionally supplied with a COA alongside the COC.

The COA is specific to each batch produced and it provides a transparent, comprehensive breakdown of the true contamination potential and composition of the product.