Our capabilities

Gekatex own the process – from sourcing to distribution

Security of supply

We have the ability to scale our solutions to meet the requirements of our customers.

Owning the entire manufacturing process from the sourcing of raw products to distribution, means we are empowered to create and develop new and innovative products, ensure the highest levels of quality control and tracking and ramp up production at short notice to meet the challenge of our customers.

Our integrated international network enables us to support global customers and provide security of supply for our products.

-

Sourcing

We source fibres and the raw ingredients for our products -

Material development

We explore the best materials, combinations or formulas to meet the challenge the product will address -

Manufacturing

The production process is defined and the item is manufactured in-house -

Packaging

Our products are controlled and packed on-site. Products for critical applications are packaged in a cleanroom environment -

Delivery

Our global delivery network ensures that our products are available when you need them

Technical know-how

Our in-house laboratories help to ensure the highest quality products and the ability to innovate throughout the manufacturing process. Our industry experts are ready to answer any questions and can refer to the lab for specific product testing.

All our products are supplied with a Technical Data Sheet.

Are your cleanroom consumables really clean?

Many suppliers to the cleanroom industry provide their products with a Certificate of Conformity (COC) to demonstrate alignment with regulations. This document certifies that the product is compliant to the required industry specifications, as outlined by the IEST.

But, the COC only provides a top-level, average certification for the product. With this approach, the cleanliness of the product is specified to a range – denying the customer the clarity and opportunity to make an informed choice on the true cleanliness of the consumables.

Unlike many other manufacturers of cleanroom consumables, Q+ products are supplied with a Certificate of Analysis (COA) alongside the COC.

The COA is specific to each batch produced and it provides a transparent, comprehensive breakdown of the true contamination potential of the product.

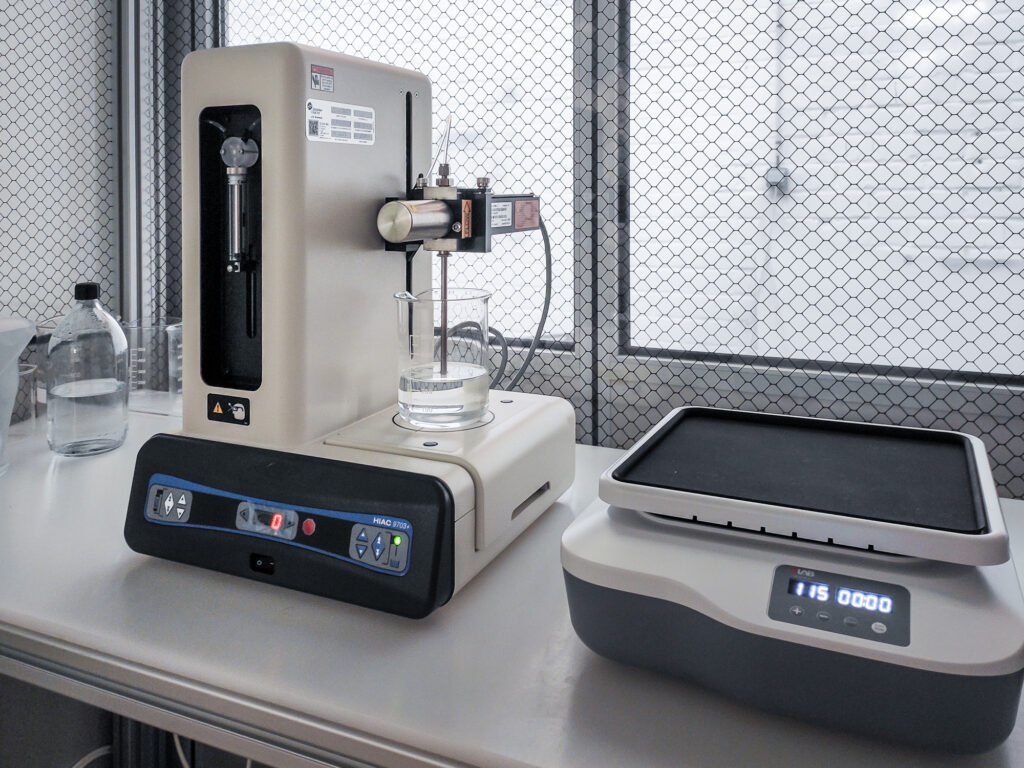

Liquid Particle Count

Our dedicated lab and Liquid Particle Count (LPC) capabilities, enable us to complete our analysis in-house. Further to the LPC, the COA contains an analysis of the potential for non-volatile residues and ion contamination.

We measure the LPC to demonstrate in the most accurate way the cleanliness of the wipe. This involves first soaking the wipe in ultrapure water and agitating it to simulate use for 5 minutes. The water is then removed and analysed by the highly sensitive machine to determine the particle and fibre count.

This is used to calculate the number of particles per m2 and all the information is recorded on the COA.

Q+ – precision products for critical environments

Gekatex Q+ cleanroom consumables (including wipes, mops and robot covers) are designed, engineered and controlled in Europe and manufactured to ensure minimum contamination.

The entire process takes place in-house – this means that our products are both, fully customisable and fully traceable and supplied with a certificate of analysis.