The Gekatex G-Light PQE is a surface inspection torch, designed to easily evaluate cleanliness and highlight marks or particles that could impact the finish quality of the end product.

Many manufacturers still rely on simple visual checks on tools and surfaces to maintain quality in their processes.

If the surface is not inspected and prepared properly in the initial stages of production, the end product will never achieve the best results. A clean surface – free from grease and particle contamination – is key to ensuring a flawless finish, avoiding costly repairs, or stopping the part being discarded altogether.

Eliminate additional processes

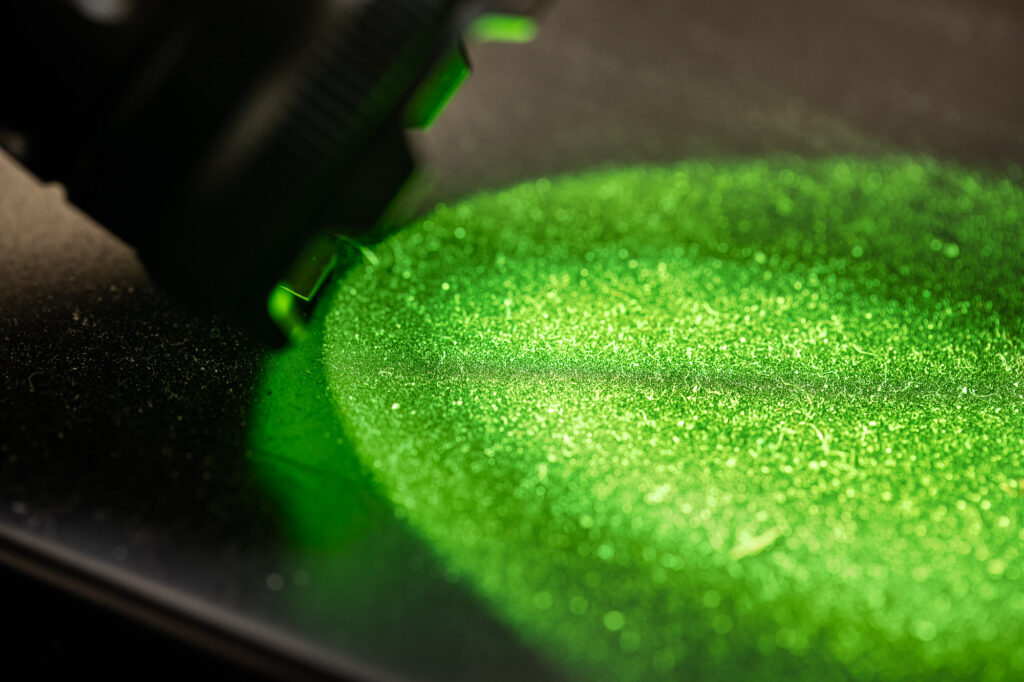

Identifying surface contaminants can be a time consuming and costly exercise, with darkrooms and UV lighting providing an additional step in the production process. The G-Light PQE’s integrated green filter increases visibility and simplifies the identification of fibres and grease marks on surfaces. This eliminates the need for expensive equipment and can be integrated into an existing production line, optimising workflow and easily implemented.

Easily identify grease marks and particles

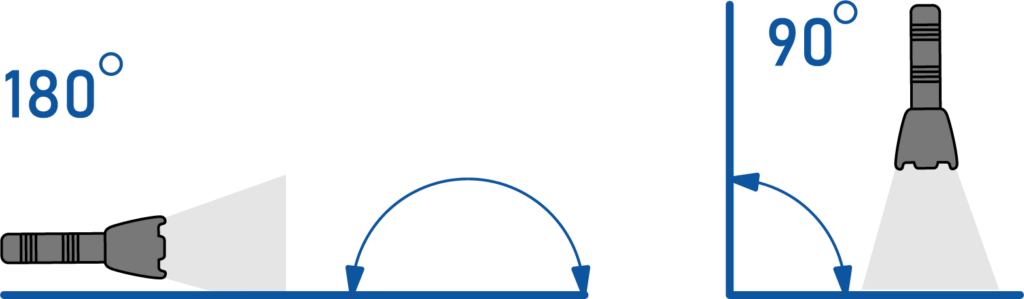

By using the torch at a 90-degree angle, the operator can easily identify grease and finger marks. At a 180-degree angle, fibres and dust on surfaces become more visible. Once the contamination type has been established, the user can decide on the best technology, or process to remove it.

Where is G-Light PQE used?

The G-Light PQE can be used to check surfaces, tools and parts before and after painting, to keep particles and contamination at minimum levels during this critical stage. The torch plays an important role in several large European organisations manufacturing operations.

A high-end sport car producer and Formula 1 team in England, use our lamp to monitor the cleanliness of its moulds before applying realising agent for composite parts. The G-Light PQE is used to ensure no dust or particles will mark the surface, or impact the high standard of the parts being produced.

Also, a very large European Tier 1 plastic part manufacturer has made use of the G-Light PQE compulsory to maintain quality throughout the production cycle.

G-Light PQE is fully rechargeable and is constructed from hard anodized aluminium and stainless-steel, ensuring long-lasting performance and resistance to wear and tear.

Get in touch with our experts to find out more about Green Light PQE here