We supply multiple products for all stages in the automotive process – our team of experts will help you choose the right product for your application.

We recognise that our products need to be more than simply technically efficient at achieving a single task – to be truly effective – they need to contribute to broader production success and outcomes, such as reducing cost and waste. Our products are present throughout the OEM automotive process, from stamping to final assembly.

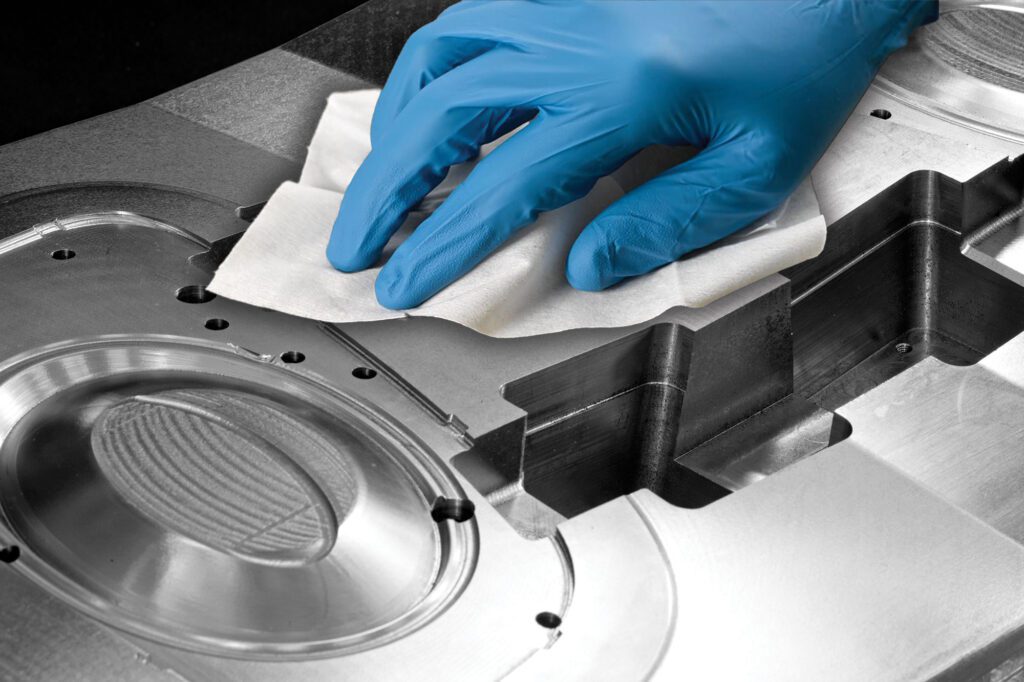

Stamping & injection mould

The first part of the process is forming metal and plastic into the required components. Our mould cleaning products have been developed to optimise your process, reduce waste and extend the life of your moulds.

Our releasing agent wipe allows the operator to apply the product in a uniform manner without over-spraying the surface or emitting airborne VOCs.

The various cleaning operations throughout the manufacturing cycle (preventive – inspection – maintenance – major maintenance) require specific wiping properties. We’ve combined the optimum wipe with the best chemicals for the application.

Body shop

Our Botprotek robot and industrial protection products are provided based on your budget and requirements. They are designed to reduce the potential for equipment damage in detrimental environments. Our covers will help you to protect your capital investment and ensure better ROI from your robot.

Gekatex solvent wipes have been specially developed for degreasing and cleaning car bodies, they are extremely hard wearing and resistant to the most aggressive solvents. These wipes are highly absorbent to remove excess solvent and spills and expediate your process.

Cataphoresis

Our backing pads will help you to remove any imperfections and prepare the surface for the cataphoretic coating to protect the surface from corrosion.

Once the surface has been sanded and polished, our tack rags have been developed to efficiently capture and retain dust, particles and lint that could affect the adhesion or quality of your surface treatment, whether it is painting, coating, lamination or other assembly process.

Mastic application

Efficiency is key in the automotive process and our experts will help you to find the best solution for the protection of surfaces, along with the best way to remove excess product from them.

Gekatex Technical Wiping solutions are manufactured from different fabrics and engineered materials to provide the best outcome in your application. Our wipes ensure effective solvent, sealant and glue cleaning, degreasing and absorption.

Robot and industrial covers are also beneficial to protect equipment at this stage.

Paint booth

Our robot cover solutions include:

- Electrostatic Discharge (ESD) technology, for safer operation in potentially Explosive Atmospheres (ATEX) – our anti-static covers achieve ISO 80079-36 standard to prevent the risk of static sparks

- Anti-Static Fire Retardant (ASFR) covers

- Cleanroom certified – manufactured and air cleaned to ensure minimal contamination

Inspection area

The inspection area is key to quality control and ensuring the best product moves out of the door. Our grinding, sanding and polishing solutions are used daily in a diverse range of industries – from car detailing and carpentry to wind turbine production and oil rig maintenance.

Our compounding, polishing and finishing foams are available in multiple colours, sizes and shapes to suit the application and ensure the most efficient process.

Assembly

This is the final stage of the automotive process, at which the mechanical elements, the driving position, mirrors and the interior trim of the vehicle are all integrated.

Our wiping solutions ensure surfaces are prepared for the best bond and excess sealant and glue can be easily and efficiently removed.

Contact our team to find out how we can help you to improve your process.