Our presaturated wipes offer convenience and consistency on top of increased safety and efficiency

-

Reduce cost

By improving the efficiency of your process -

Lower waste

Less waste from both the wipe, and from scrap parts -

Minimise VOC

Reduce operator exposure to VOCs -

Safer

No chemical drum require, simplifying transport and storage

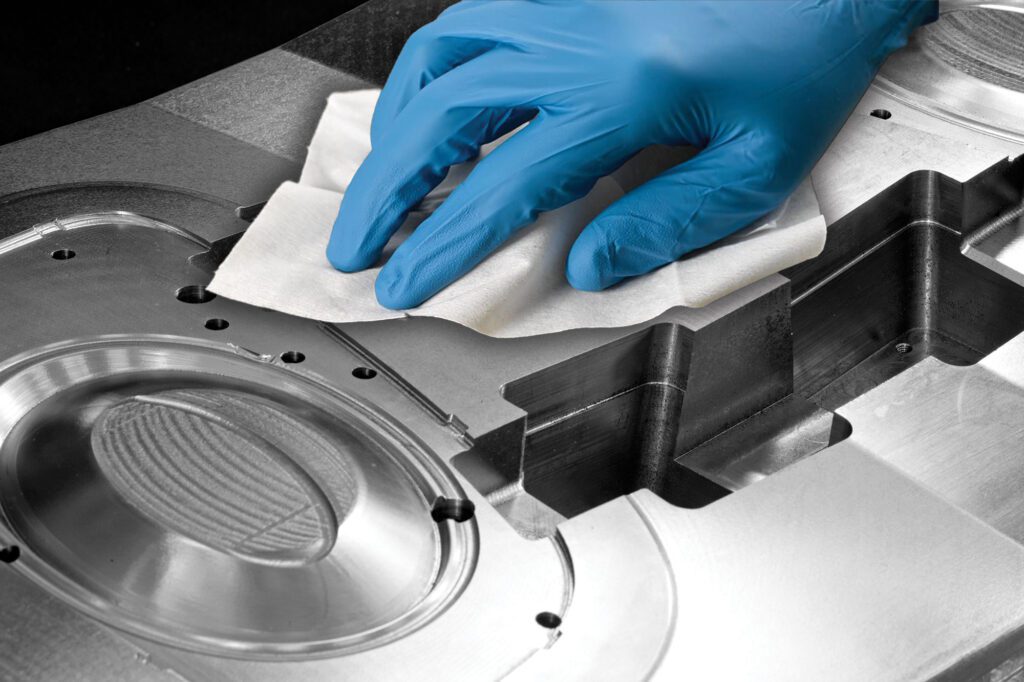

Gekatex Acusat presaturated wipes:

- Designed to clean in a single pass for efficient cleaning

- Developed to ensure a fast drying time for maximum productivity

We will work with you to identify the best solvent and wipe to help you reduce cost, improve efficiency of your process and minimise operator exposure to VOCs.

As a solvent integrator, we are experts at identifying the best wipe, (fabric/size/folding/container and distribution) and right solvent for your process, including:

- SRG

- Isopropyl alcohol

- Ethanol

- DI water

- Isopar H

- Purasolve

- 12 Solvent options

- 7 Wipe options

- Over 37 combonations

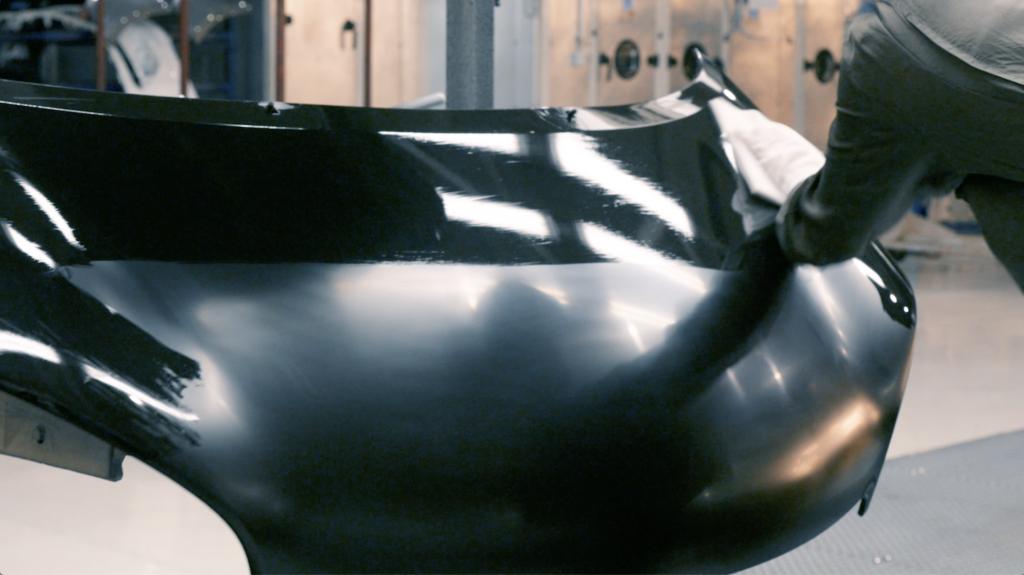

Our presaturated wipes can help you to:

- Reduce cost by improving the efficiency of your process

- Lower direct waste (from the wipe itself) and most importantly indirect waste (from scrap parts)

- Minimise operator exposure to VOCs

- Limit risk of dangerous chemical spillage – no chemical drum on-site

- Simplified transport and storage

The chart on the left indicates the amount of solvent required in each application type – presaturated wipes reduce solvent consumption by up to 50%

Your process, your product - our wipe

If we can’t source the solvent directly, we can provide our specialist dry wipes cut to size and ready to saturate. We will calculate the amount of solvent you will need to add and provide the ideal packaging solution to saturate and store the wipes in.

We can even do the messy work so you don’t have to. Just provide us with the solvent you would like and we will presaturate!

- WIPE selected for performance and compatibility with the liquid

- SOLVENT liquid chosen for a specific task

- PACKAGING developed to maintain wipe integrity & support the most efficient process